Laser cutting

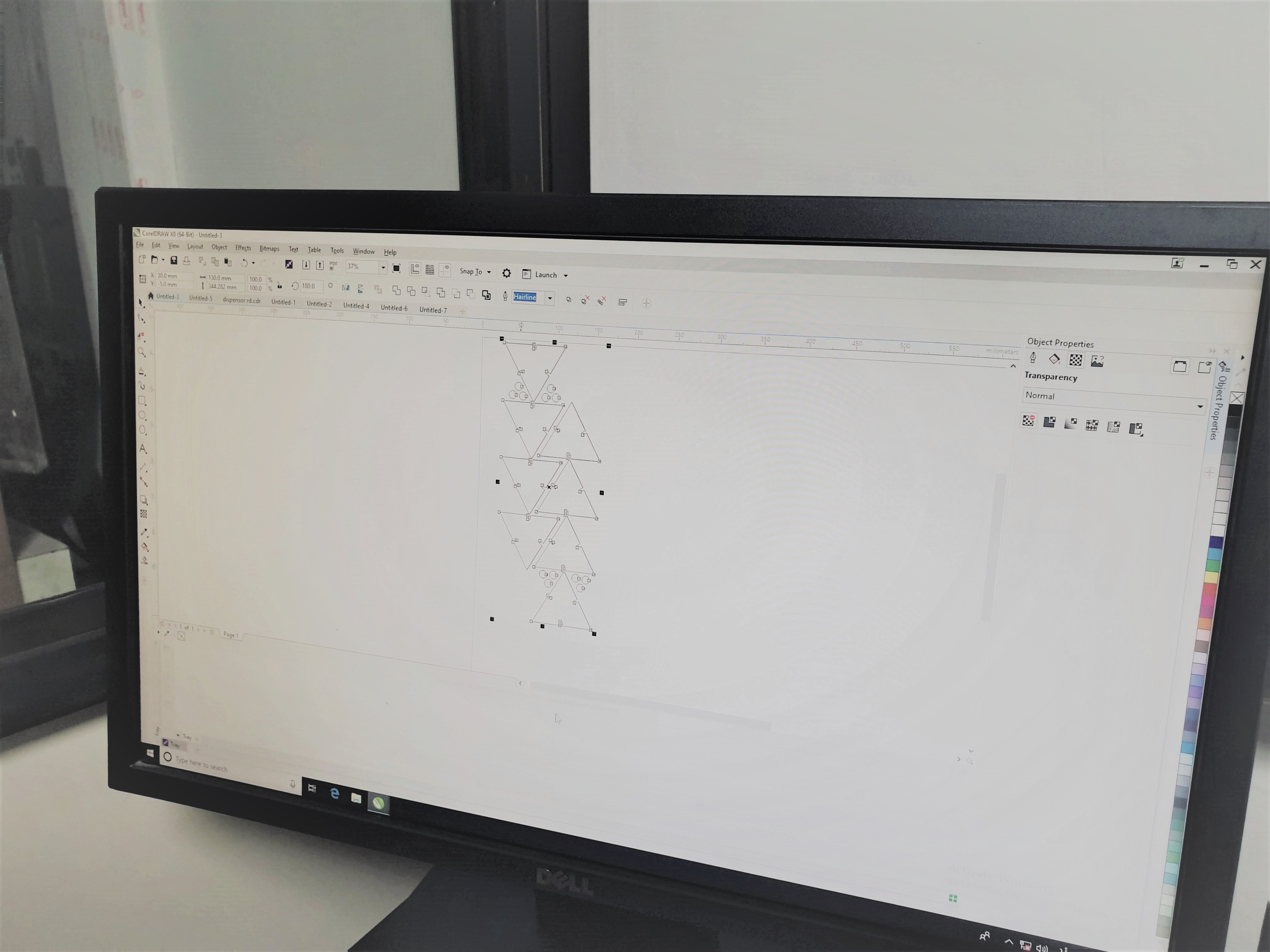

Inputing the vector into Coral Draw

From the assembly of the model developed in Solidworks, the sketches of the individual parts are exported as .dwg files which are them opened in Illustrator to convert them into .svg vector file. These vector files are then imported into Coral draw and the proportions are set to achieve a 1:1 scale. This asiignment was done teaming up with my talented friend, Himanshu

Making the press fitting comb and model

For the tickness of the MDF board, an appropriate thickness of slots should be determined. To find the right fit, the thikness is measured and a comb design is made with the various minute alterations to the thickness as shown below. T

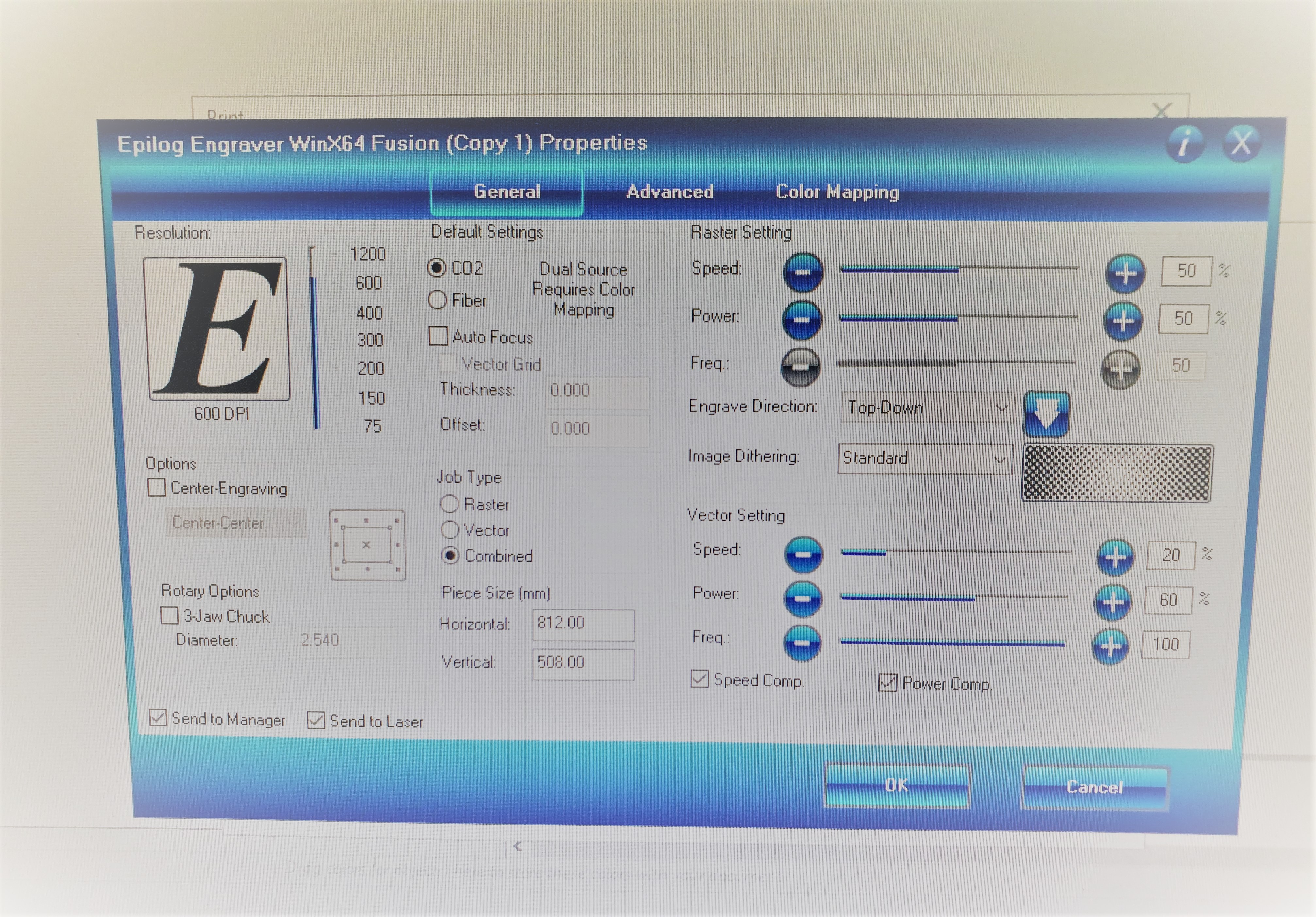

For the MDF board a setting of S=20 P=60 and F=100 was used for a clean cut without burnt edges. After the model is imported into Corel Draw, The entire vector is given a 'Hairline' thickness and then sent for cutting by giving the printing option.. After the JOB is sent to the cutter, The MDF board is place in the cutting bed. And the lazer us focused to the right height by adjusting the bed height. The exhaust is activated and then the JOB is initiated.